we are a trusted manufacturer of high-quality couplers, committed to delivering precision, strength, and reliability.

our strength lies in the perfect blend of technology, expertise, and trust. We are more than just coupler manufacturers—we are problem solvers, innovators, and partners in your growth.

Choosing the right partner for your coupler needs is crucial—and that’s where we stand out. we don’t just manufacture couplers; we deliver trust, strength, and reliability.

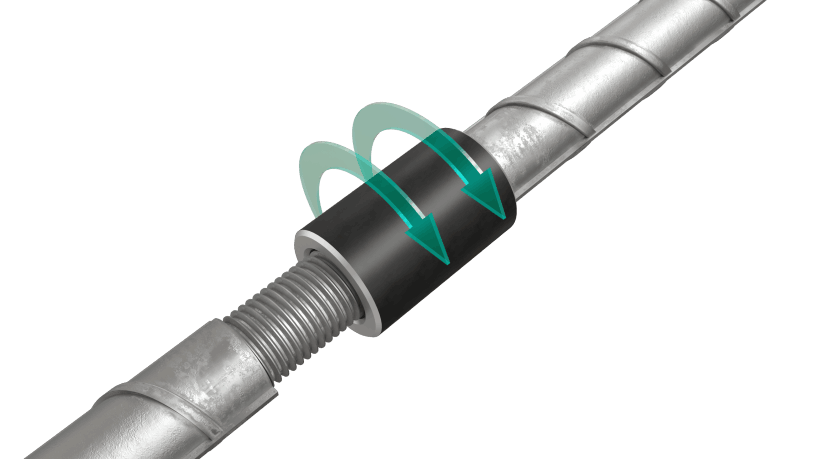

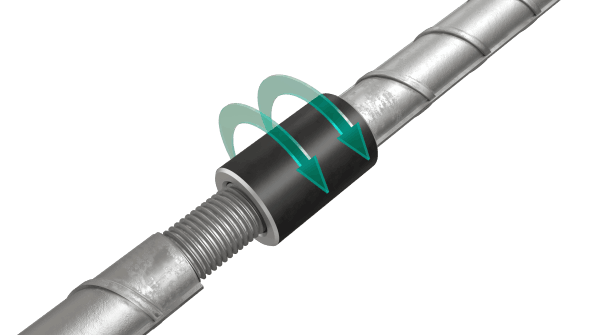

Designed with continuous parallel threads for easy installation, these couplers ensure high tensile strength and seamless bar alignment.

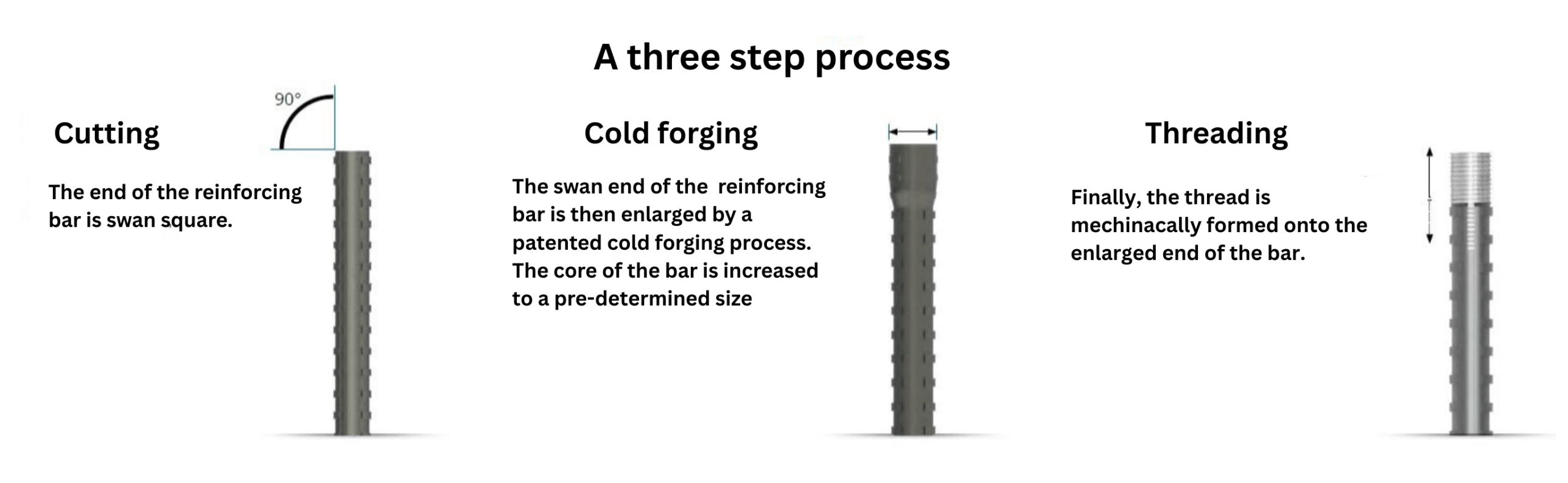

These couplers are created by increasing the bar diameter through cold forging, followed by threading—providing a robust mechanical joint with enhanced strength

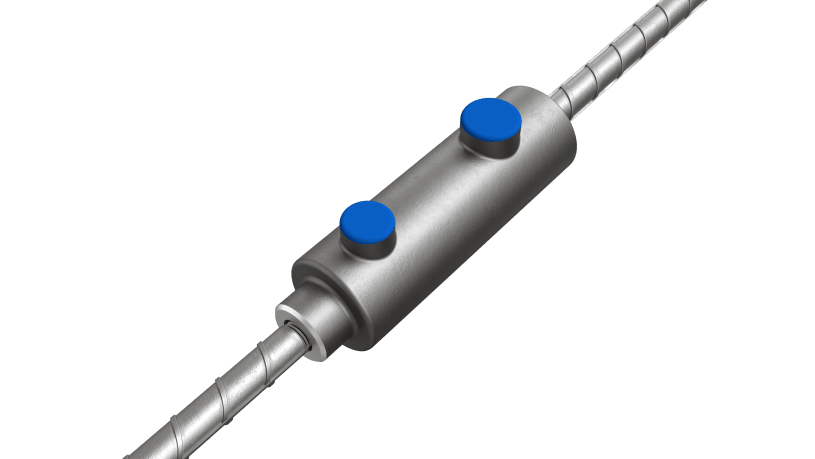

Ideal for retrofit and repair applications, MBT couplers do not require bar end preparation or threading, making them perfect for constrained environments.

These couplers use a tapered thread system for faster engagement and easy tightening, providing a secure and durable mechanical splice.

Specially designed for precast construction, these couplers allow for efficient and secure connections between precast elements using high-strength grout.

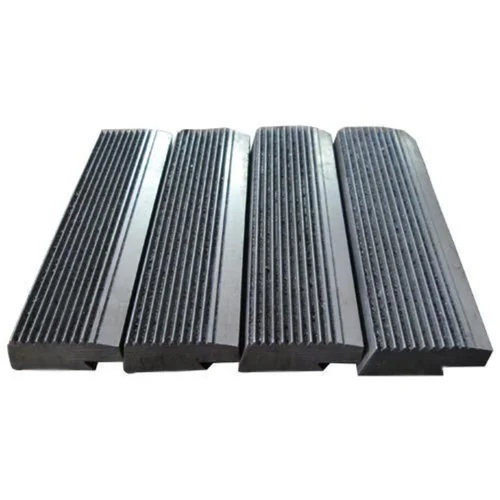

A threading chaser is a specialized tool for cleaning, restoring, and repairing existing threads.

Designed with continuous parallel threads for easy installation, these couplers ensure high tensile strength and seamless bar alignment.

These couplers are created by increasing the bar diameter through cold forging, followed by threading—providing a robust mechanical joint with enhanced strength.

Ideal for retrofit and repair applications, MBT couplers do not require bar end preparation or threading, making them perfect for constrained environments.

These couplers use a tapered thread system for faster engagement and easy tightening, providing a secure and durable mechanical splice.

Specially designed for precast construction, these couplers allow for efficient and secure connections between precast elements using high-strength grout.